Driveshaft manufacturing in Estonia

For all types of vehicles and special equipment

High-quality driveshaft manufacturing

We manufacture driveshafts according to individual orders or in cases where the cardan cannot be repaired.

1-year warranty

Use of original parts

Fast and high-quality service

Experienced specialists

Submit a request for the manufacturing of a new driveshaft

Fill out the application form so that we can evaluate the cost and time frame of the work. We will contact you to validate our offer.

At Auto Cardan, we produce driveshafts to the highest standards using the latest technology and original parts. This ensures maximum torque transfer and safety throughout the cardan’s lifespan.

Specification and sketches

Before manufacturing begins, our team meticulously creates detailed sketches and specifications for the driveshaft, ensuring precision and alignment with requirements. This careful planning sets the stage for the production process, where high-quality materials and advanced techniques are used to manufacture reliable and durable driveshaft.

Tube fitting and processing

To ensure the highest safety and longevity of the driveshafts, we use seamless tubes. Our specialists fit the tube according to the specified parameters. The tube ends are machined at a specific angle to create a welding seam. The tube ends are then heated and pressed together with the assembled cardan parts.

Welding

To prevent the driveshaft from twisting during welding, spot welding is performed at four points. The welding nozzle is positioned at the correct angle relative to the cardan’s axis, and the welding parameters—current strength, voltage, and cardan rotation speed—are set. To ensure a precise weld seam joint, a specific section of the flange is welded twice.

Balancing

The aligned cardan is placed in a balancing stand, where precise parameters are selected to balance the cardan. If necessary, weights are welded onto the specified points by the balancing equipment, ensuring the stability of the driveshaft.

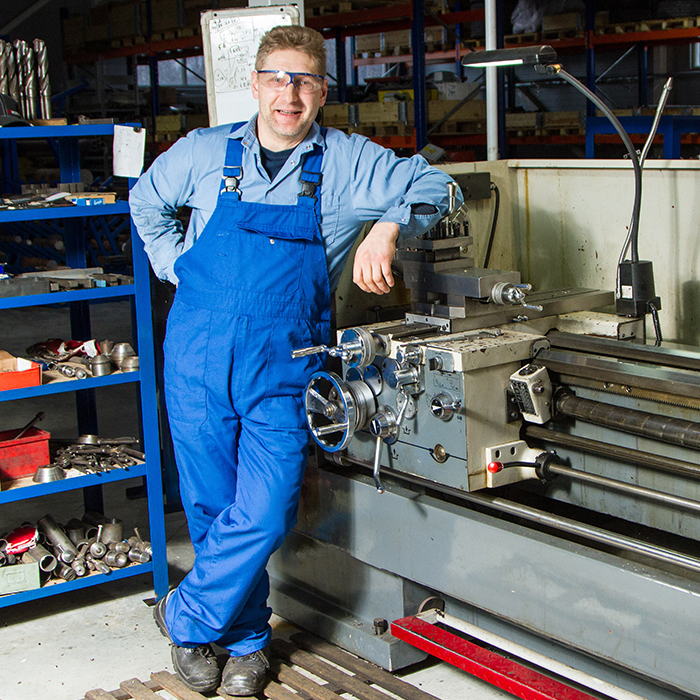

Driveshaft manufacturing facility in Estonia

Auto Cardan provides driveshaft manufacturing for all types of vehicles and special equipment in Latvia, Lithuania, Estonia, and Finland. Orders from Estonia and Finland, manufacturing is handled by Auto Cardan in Estonia.